Designed to build With COnfidence

When you partner with Skylark, you get machines that work. Throughout a project, here’s what you can expect:

Collaboration- Share ideas and ask questions about your specialty equipment, anytime.

Education- You’ll remain in the loop on machine design components so final pricing makes sense and timelines work for you.

Easy Communication- In case you need to pivot, project managers and leadership are just a phone call away.

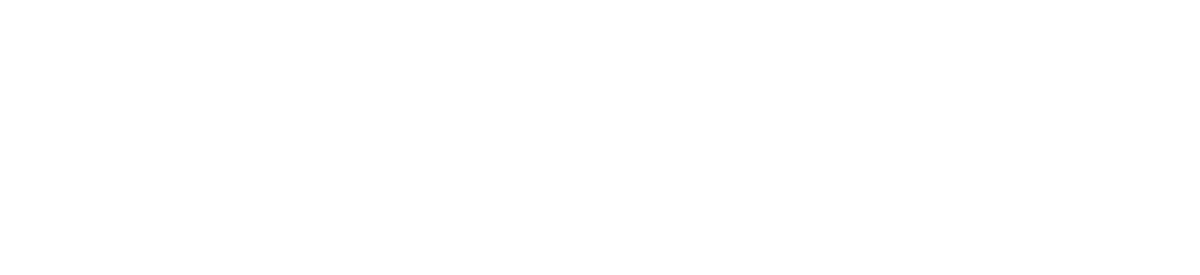

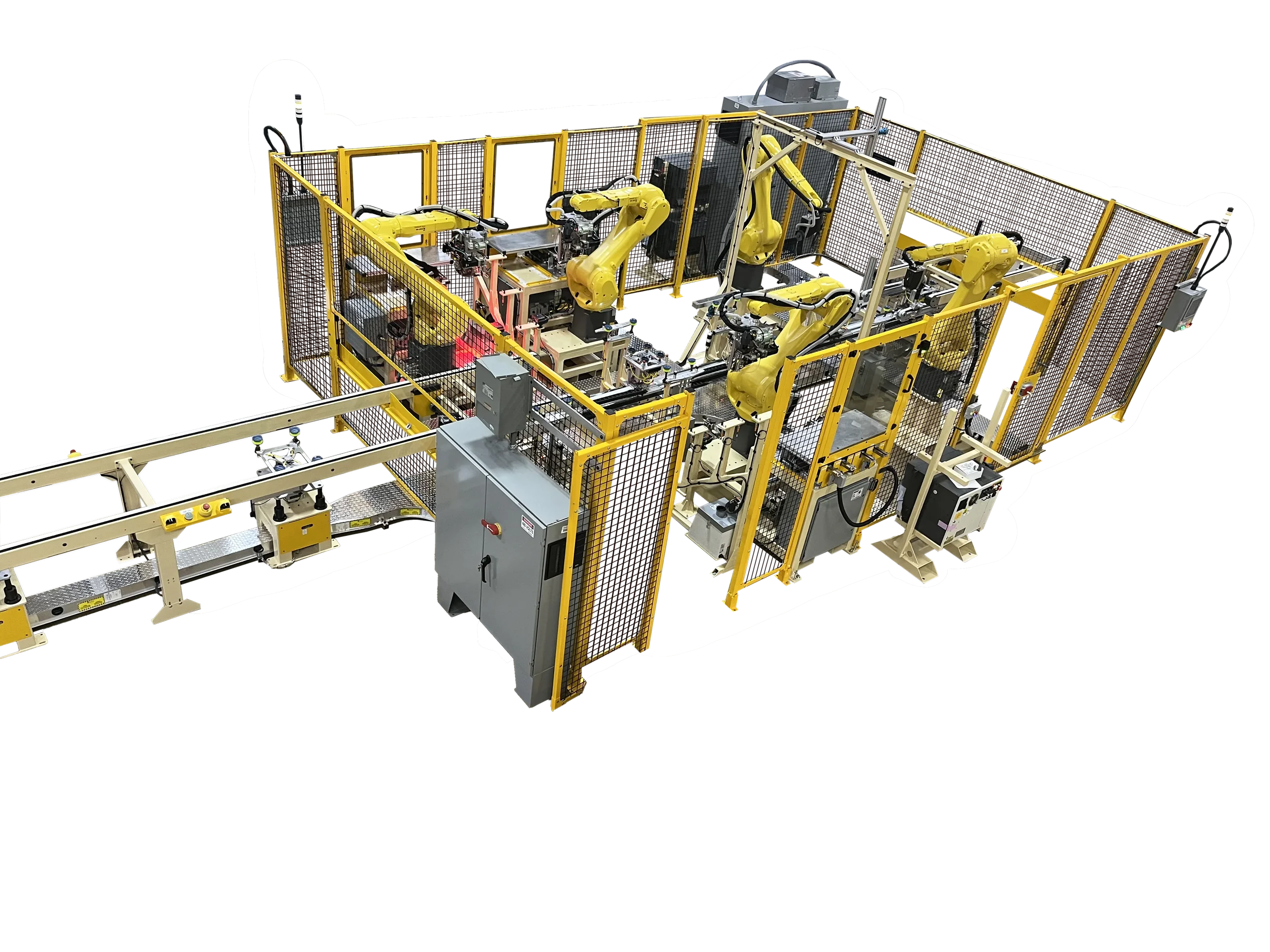

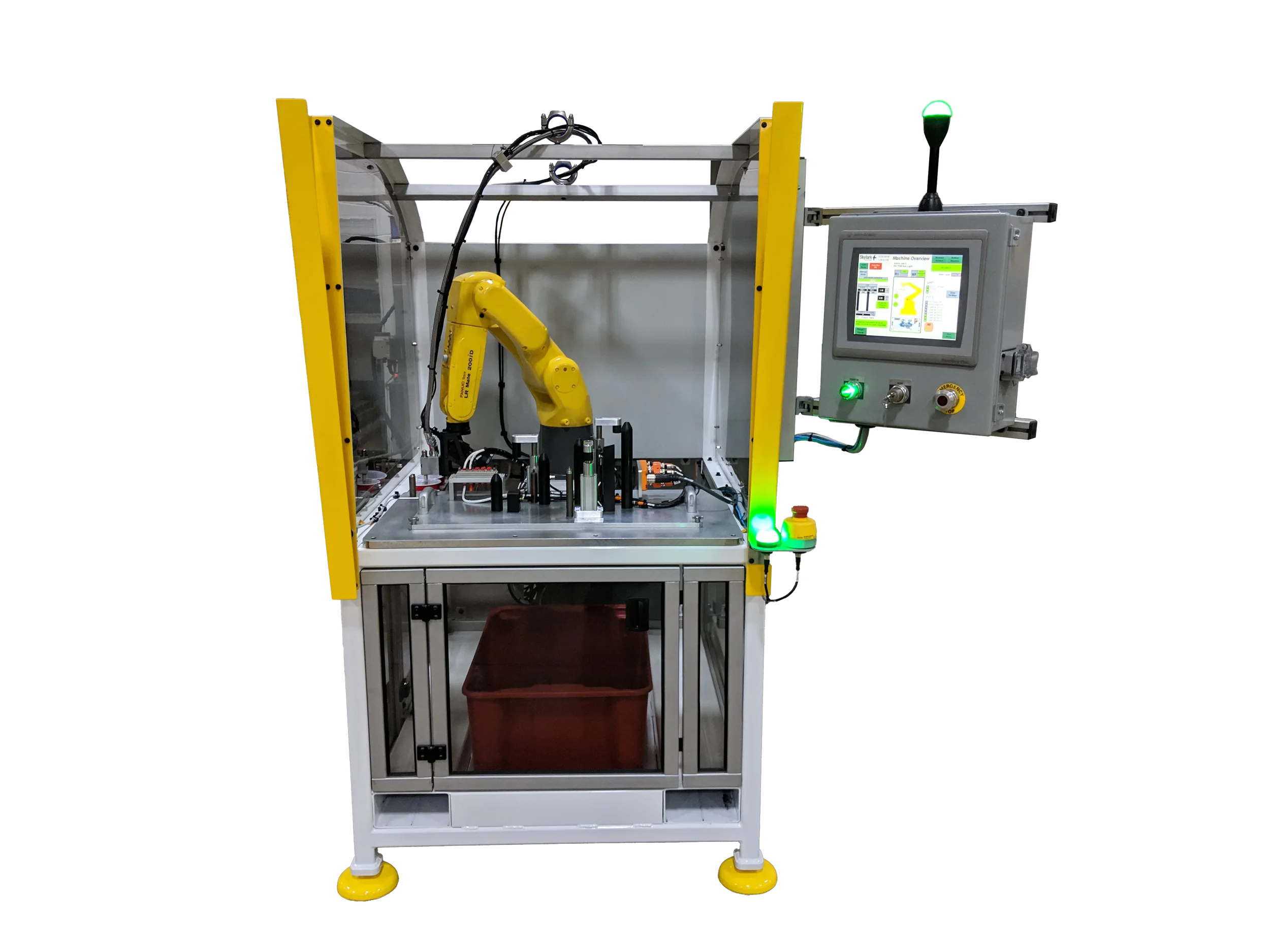

Specialty equipment we build includes (but is not limited to):

-

Integrated multiple Keyence & Cognex vision systems

Integrated PC based AI vision systems

MVI for machines can specify correct camera resolution, lenses, and light intensity and color.

-

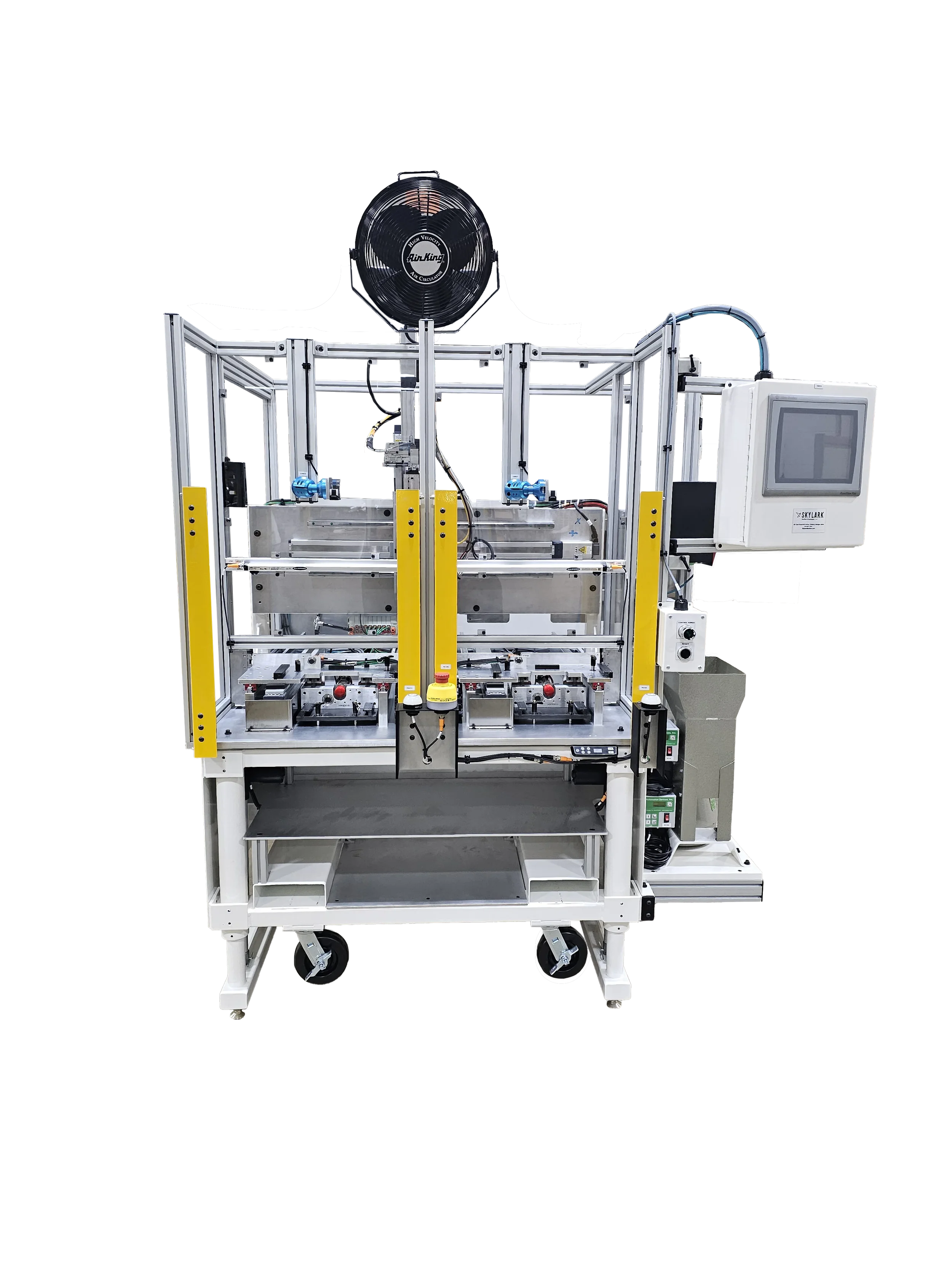

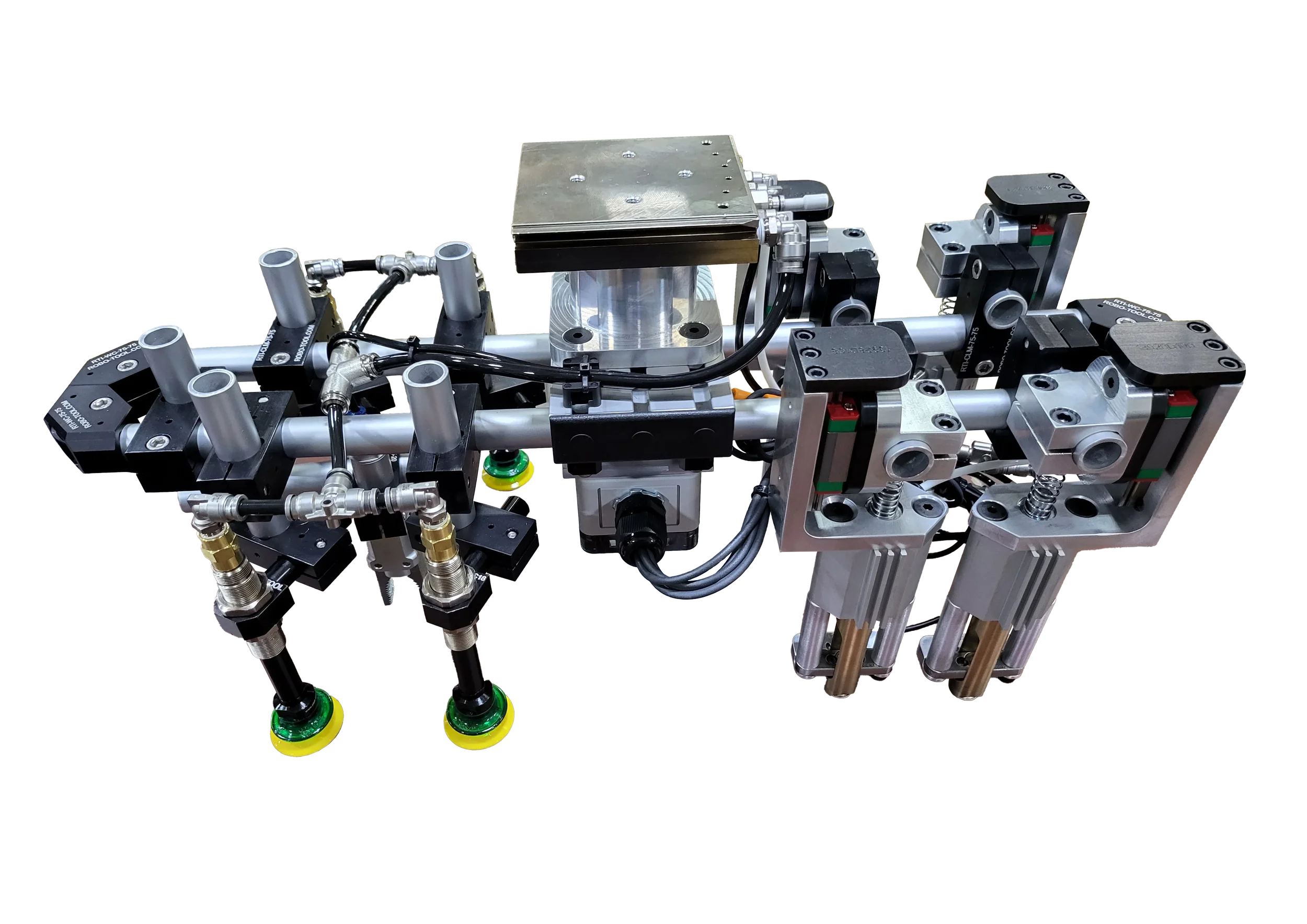

We offer manual or load clip driving machines.

-

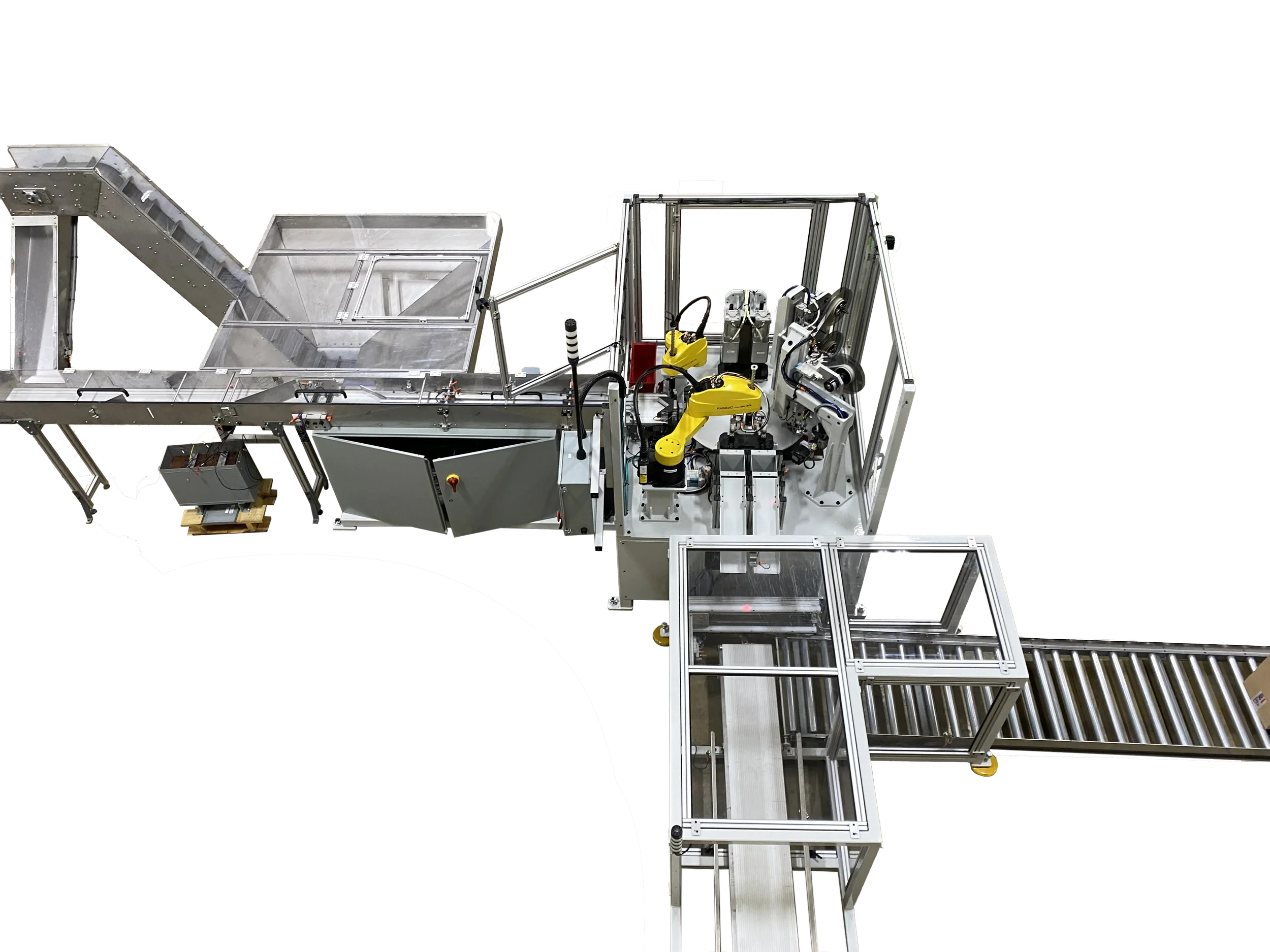

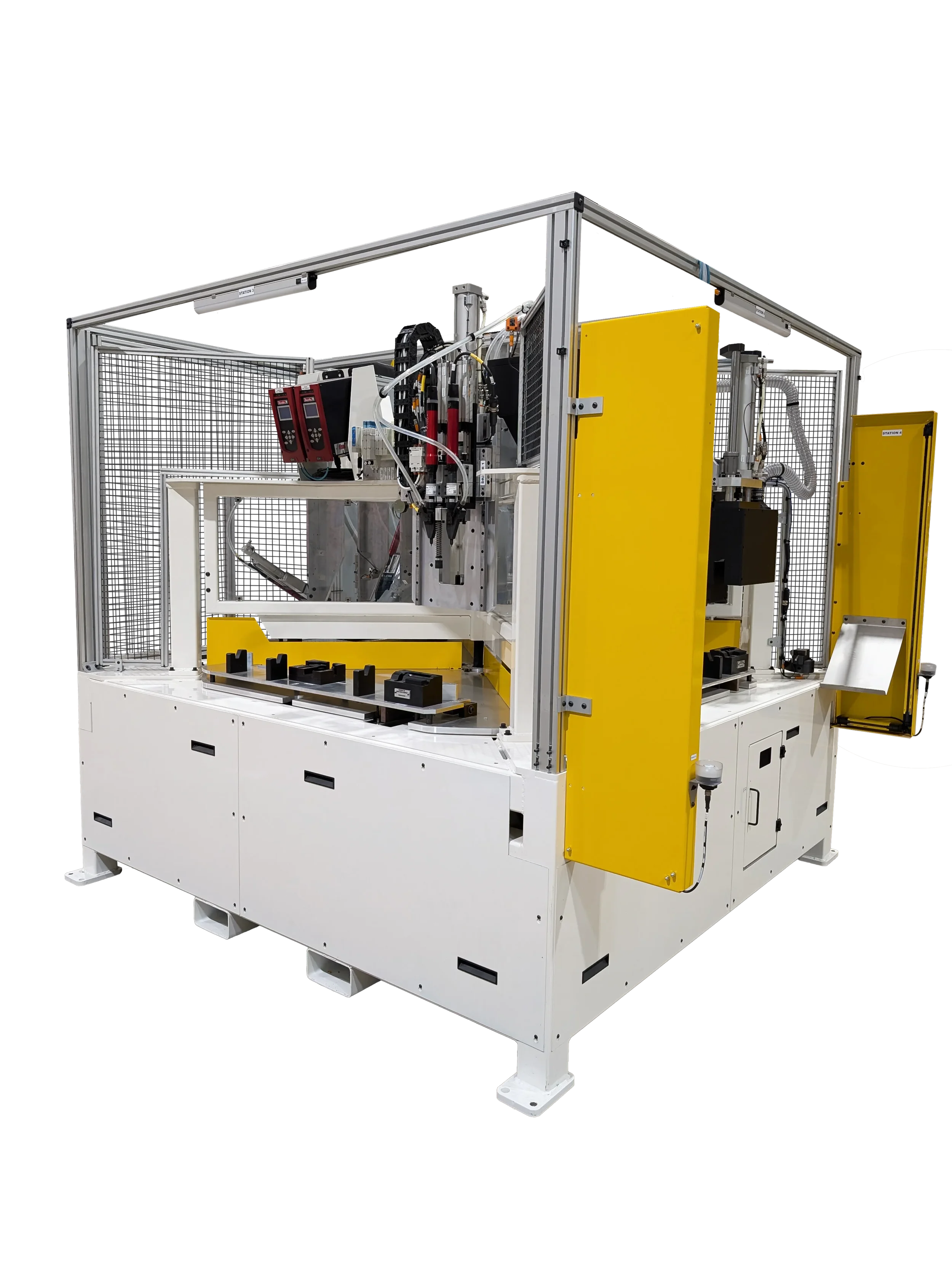

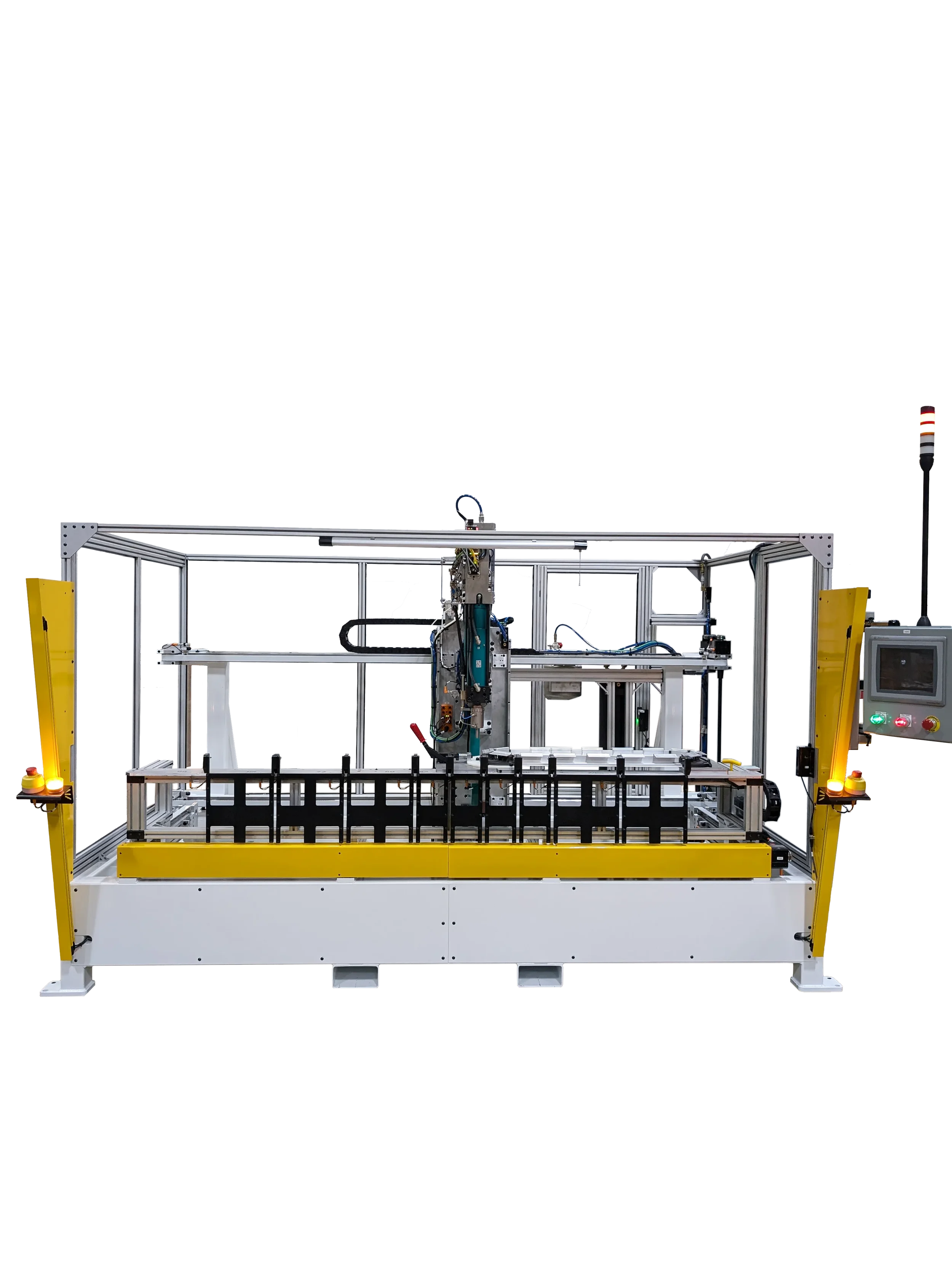

Auto de-gate

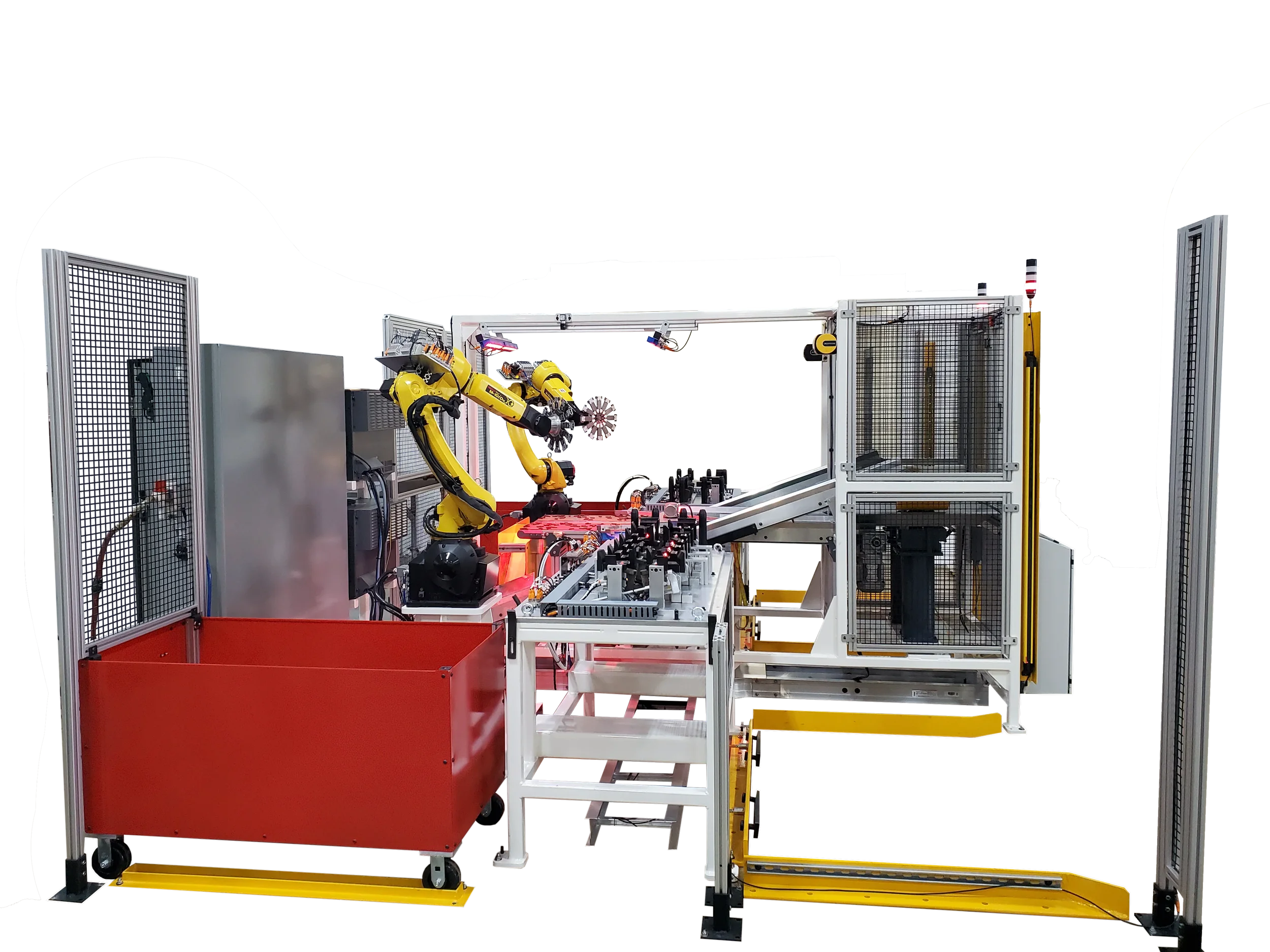

Stand-alone machines or integrated with molding equipment & robot

-

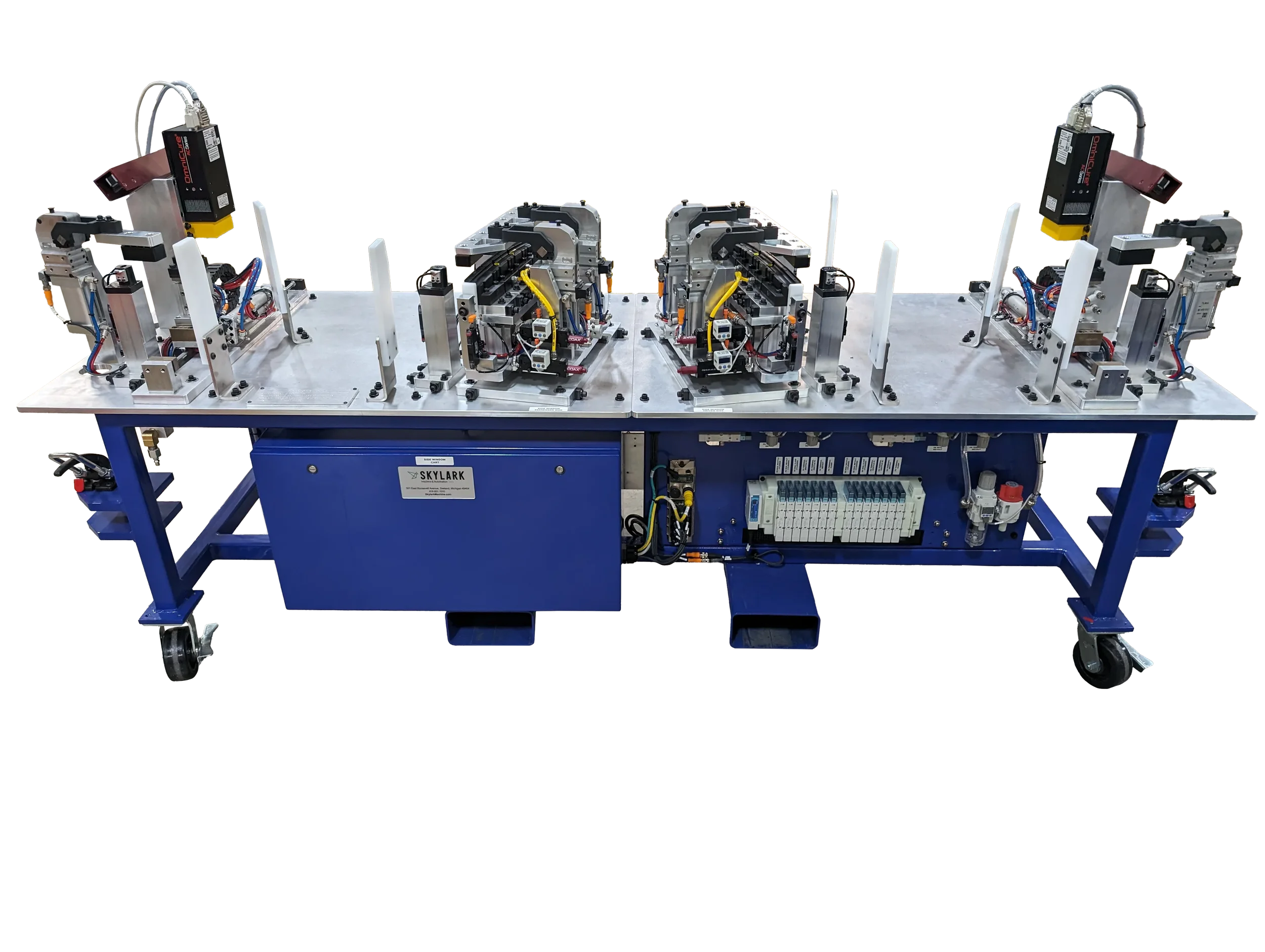

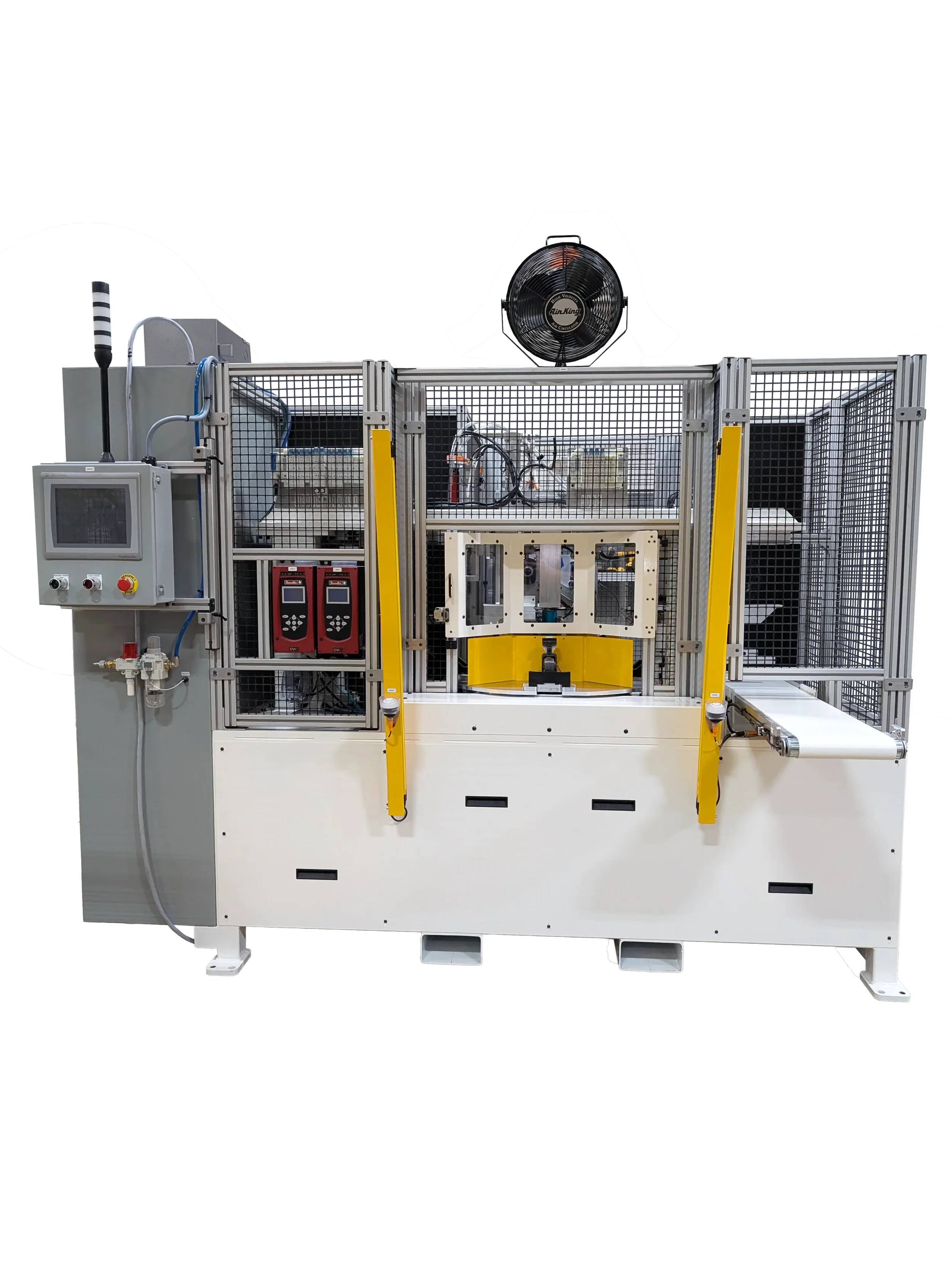

We offer:

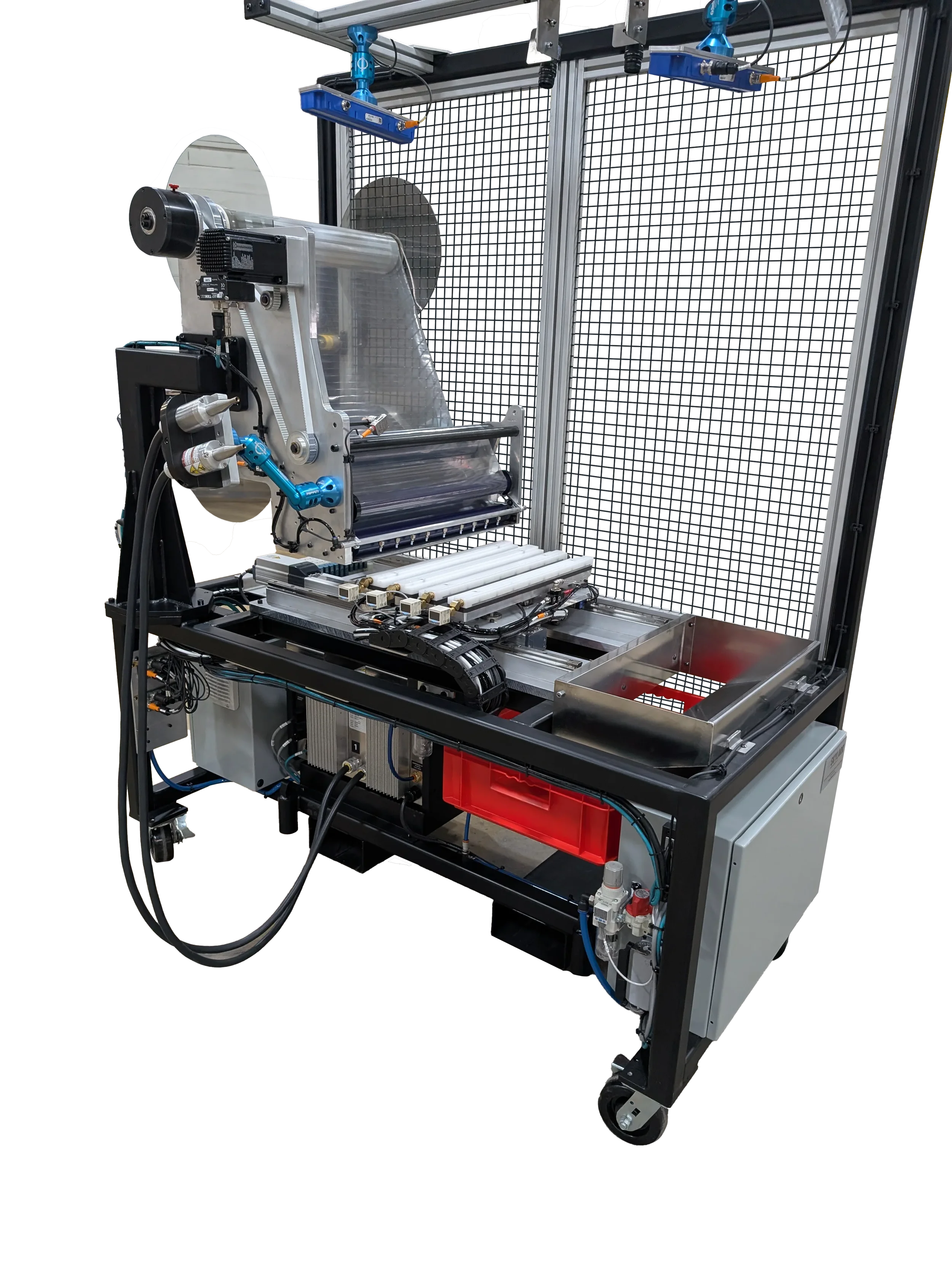

Multiple material welding, ie., fabrics and plastics

Multiple interchangeable weld tools, designed for 1 base weld machine depending on part volumes

-

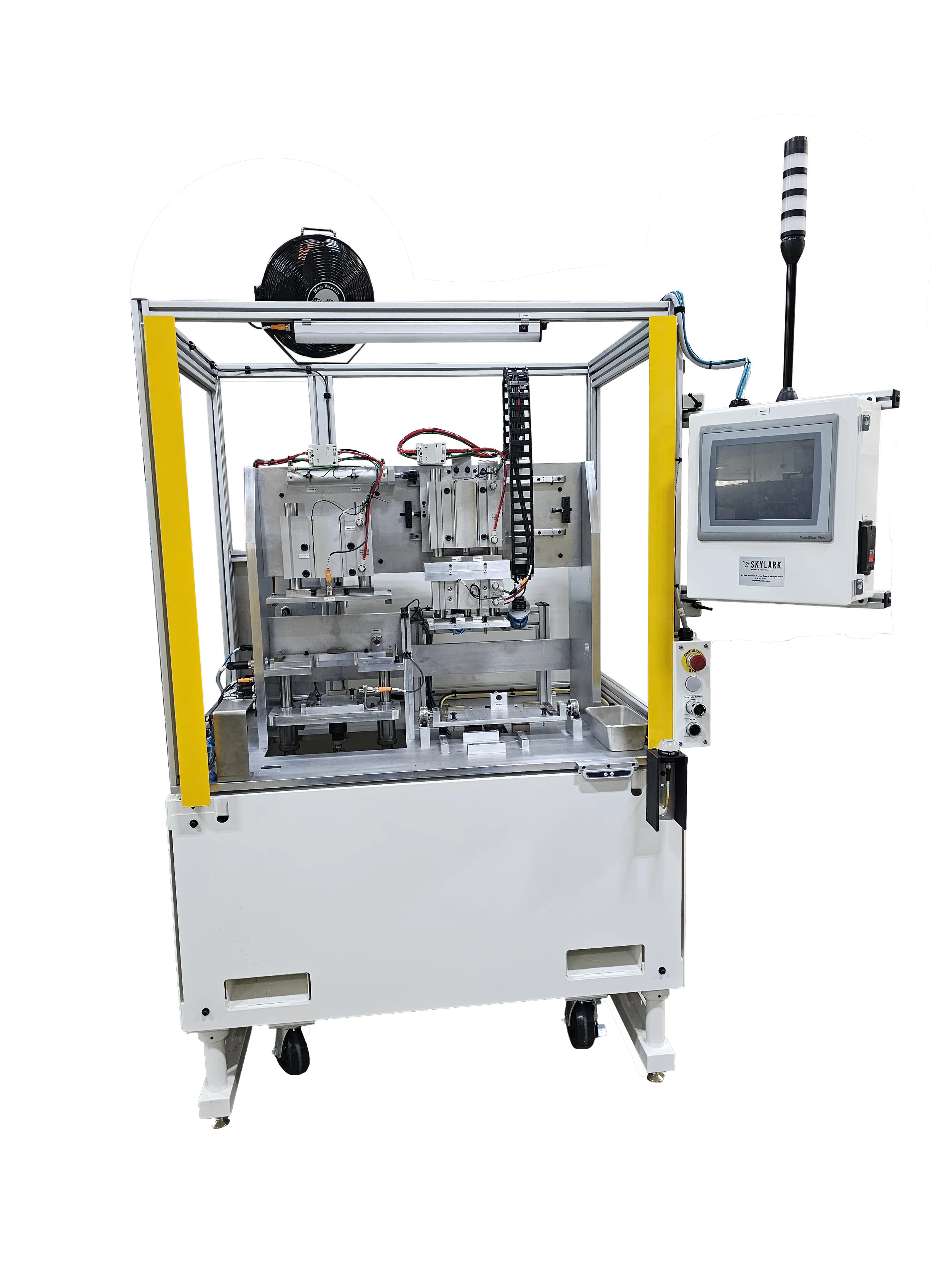

Heat staking for custom machinery

-

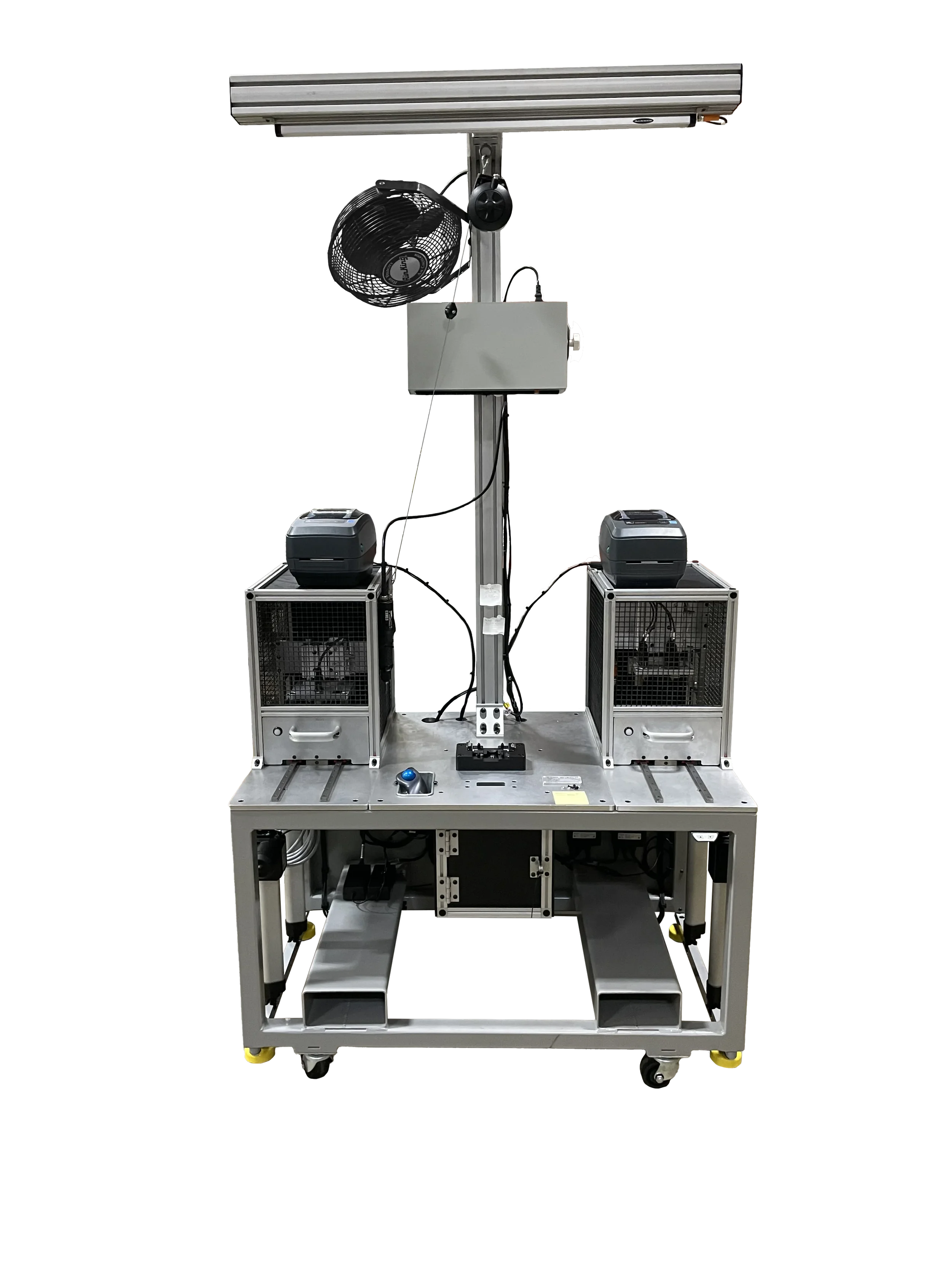

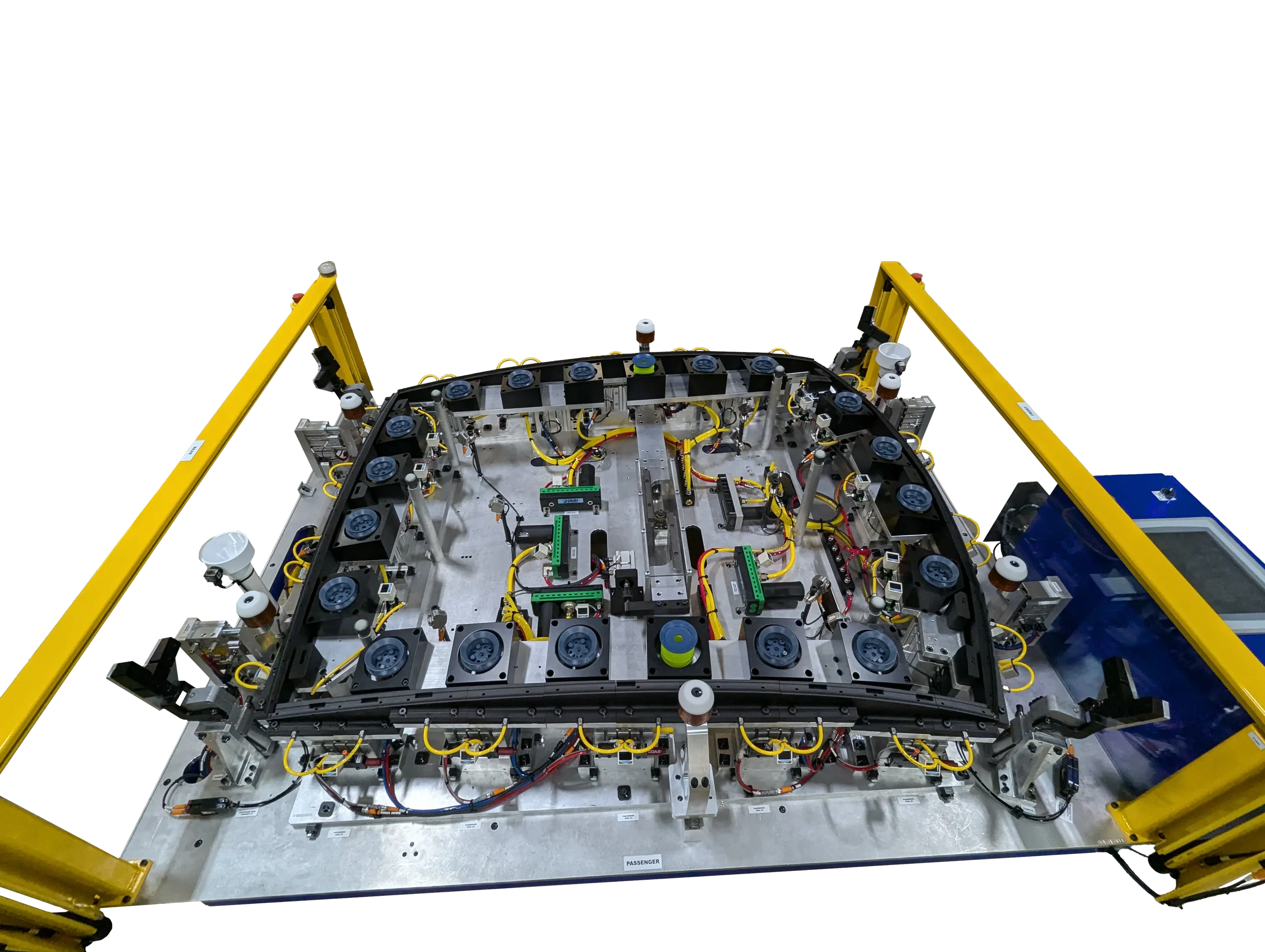

We can build/integrate PCB Testers that can test a wide range of components including:

Current

Voltage

LED Light output

Hi-pot

-

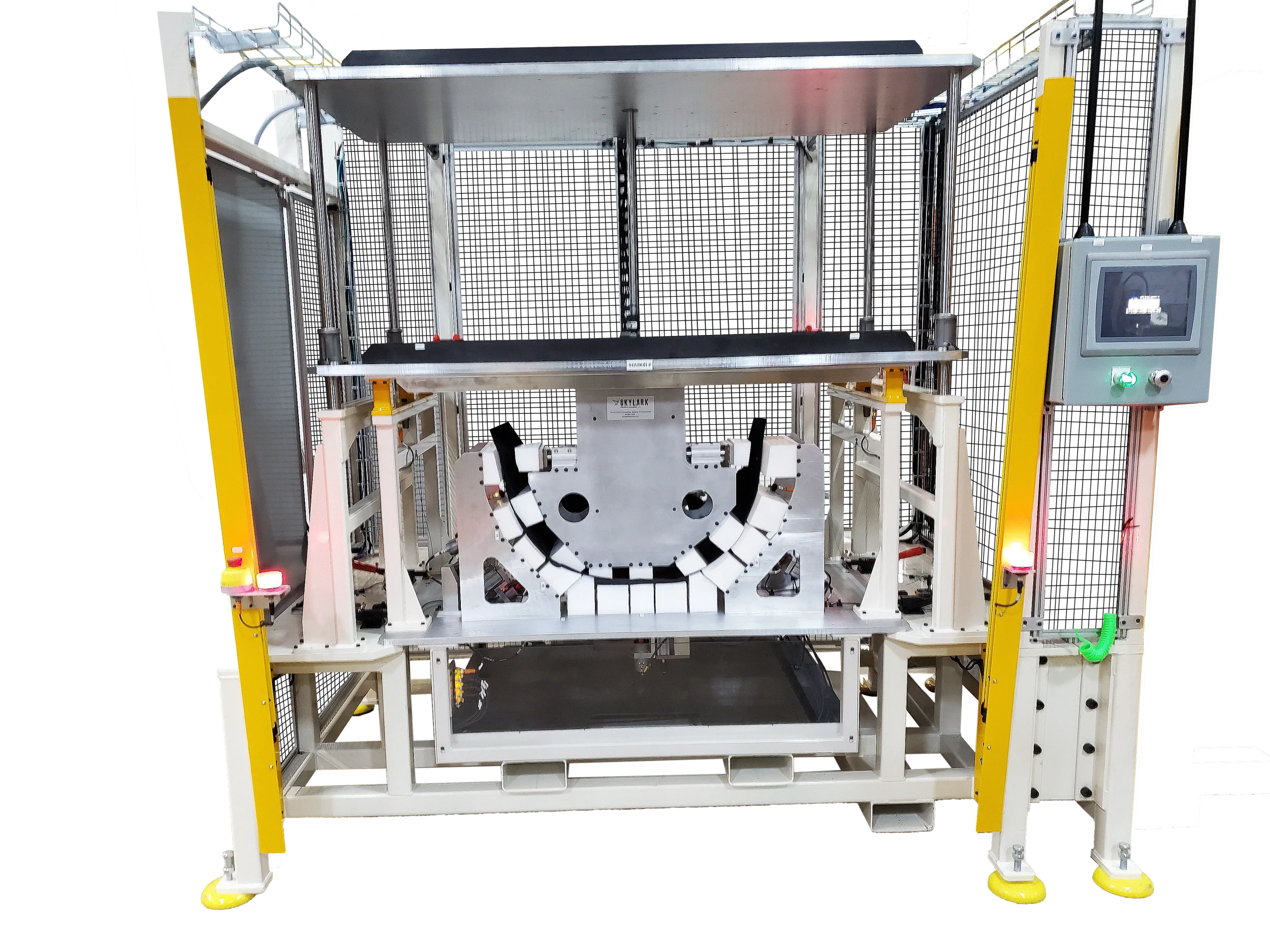

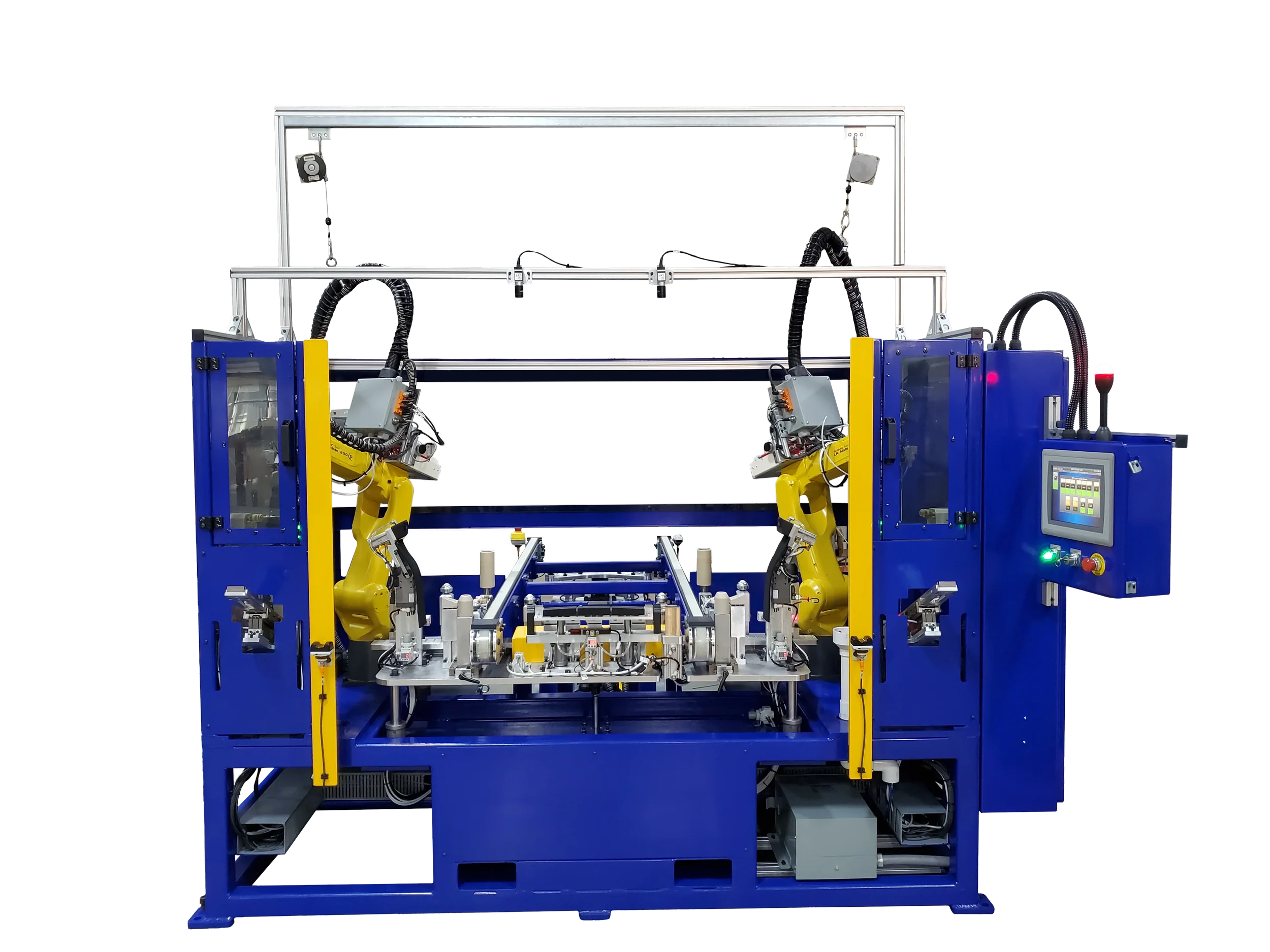

We offer general assembly based upon your specified goals and needs.

-

Pre-dispense surface treatments

Priming applications

1k & 2K auto dispensing and inspection

-

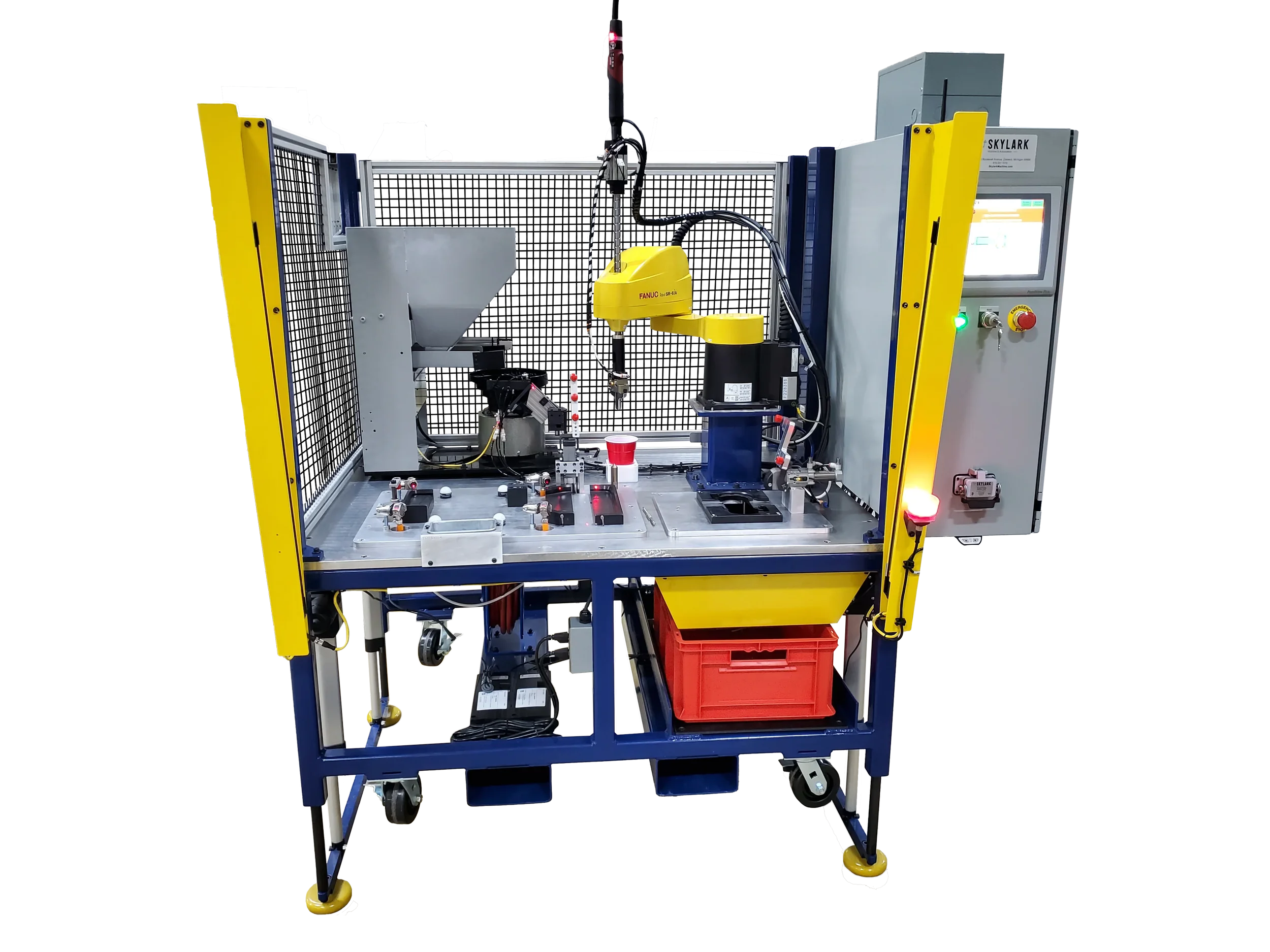

Auto clip pick and solder to multiple types of materials

Custom Automation Gallery

Reach out today for a free quote. We look forward to learning about your next project.